How is Lean Six Sigma DMAIC Process Defined?

Try to think about how effective Lean Six Sigma is in the business industry; with millions and millions of companies, businesses, and organizations constantly on the hunt to receive the best and the most amazing quality of training and certification – to their aspirations of working with the best when it comes to Lean Six Sigma Consulting, how impacting do you think the Lean Six Sigma Methodology is?

Why do you think it’s one of the most-loved and the most sought after practices and disciplines in the industry? Is it because of its classical and old-fashioned way of solving problems? Does it involve the structure of how a certain problem is defined and solved?

Lean Six Sigma is Different and Unique

To let you know, Lean Six Sigma isn’t the only methodology out there in the market that focuses on business process improvement (BPI). There are hundreds of different ways, methodologies, and strategies out there.

The one thing different about Lean Six Sigma is that it is data-driven and its approach is rather concise and straightforward, but with finesse at the same time. It’s not vulgar and it doesn’t feel rushed – Lean Six Sigma is the perfect solution that you can have for your business should you find that it needs a little bit of development and improvement.

Different Lean Six Sigma Processes

Under Lean Six Sigma’s umbrella, there is a myriad of different processes that are used and utilized to get to the bottom of the process improvement – there’s the DMAIC, the DMADV, the Five Whys, the Fishbone or the Ishikawa Tool, and many more. Among these many processes, the DMAIC stands out and it’s considered as one of the most used and the most recognized processes for BPI – and here’s why.

How is the Lean Six Sigma DMAIC Process Defined?

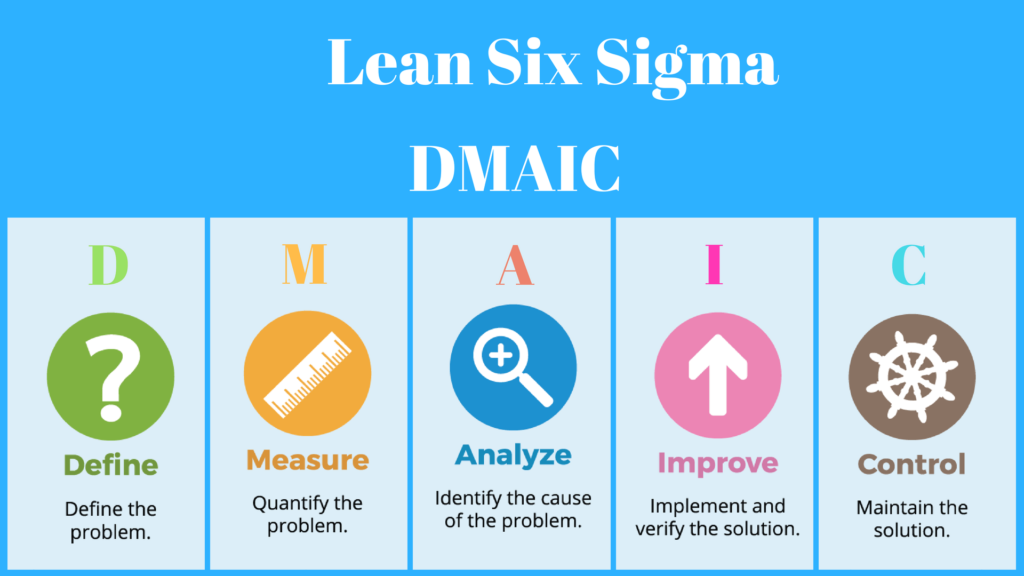

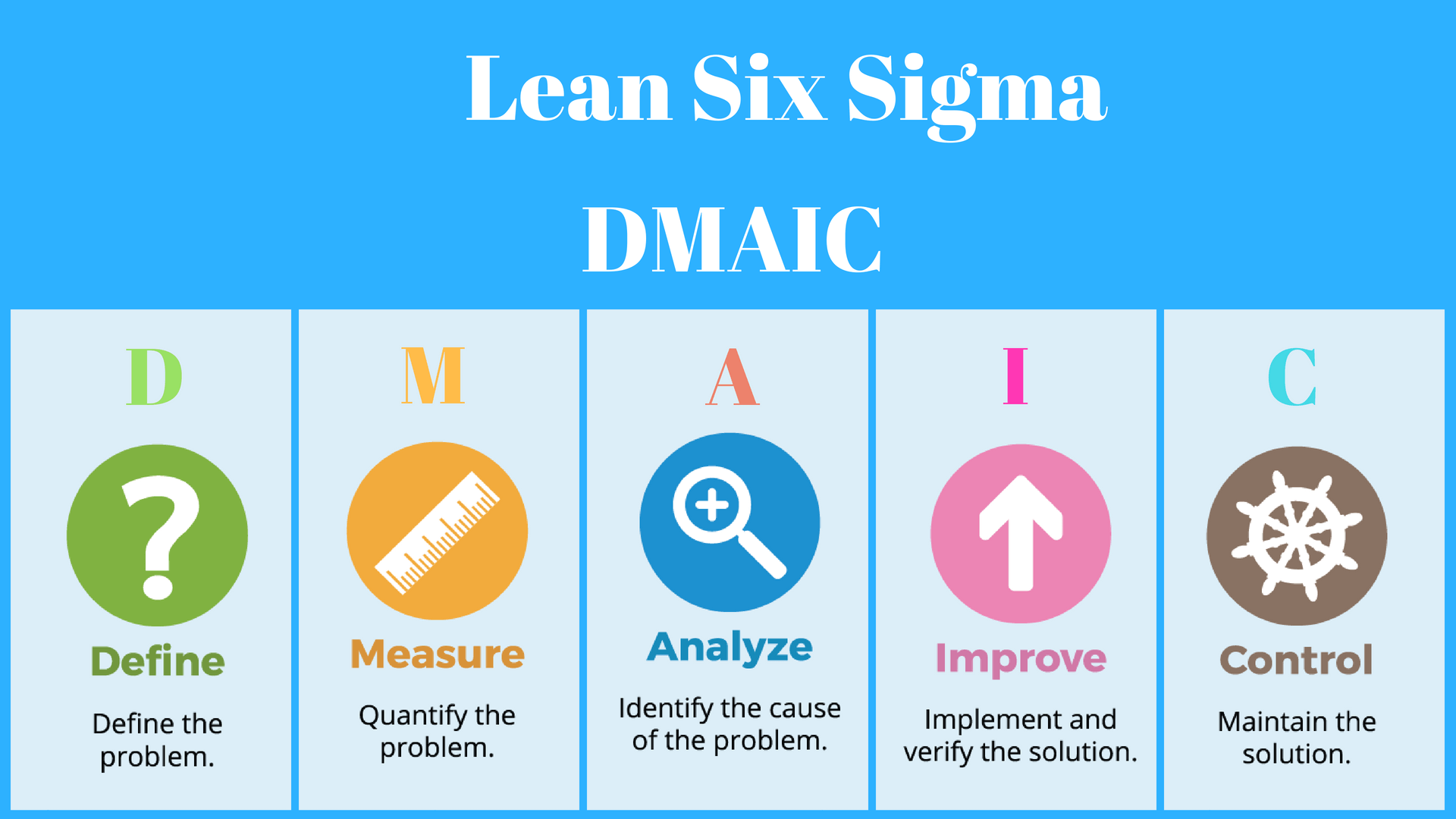

By definition, the DMAIC or the (D) – Define; (M) – Measure; (A) – Analyze (I) – Improve; and (C) – Control is the structure or the framework that is used by businesses, companies, and organizations that want to improve and enhance an existing process, system, product, or service that they have for them to cater to the needs and the wants of their clients.

Basically, the Lean Six Sigma is the medium and the fuel of that is the DMAIC structure. It’s what’s used in most procedures and processes of Lean Six Sigma and although there are a lot of different methods and strategies in it, the DMAIC remains the best and the coolest.

Learning the DMAIC

If we were to learn the DMAIC, we need to start it off by the initial steps – and it needs to flow seamlessly and smoothly to avoid any type of mishap or inconsistency. Without further ado, here’s what you need to know when you plan on learning about the DMAIC.

Define (D)

This part of the whole structure is the process in which the problem or the dilemma is defined. It involves the distinction of what the problem is through the problem statement, the erasure of all the irrelevant factors, and the like. Basically, this part primes the entire DMAIC process as this is where everything will start – it’s where your DMAIC process will be based on.

Measure (M)

Going over to the next step, which is the Measure step, is the process in which variables are measured over a scale where it would dictate whether or not solving the problem would make much of a difference that it was existent. Through quantitative measurement, the problem can see its end and it will be solved in such a way that it doesn’t get too confusing. It will be in a regularized and a standardized method

Analyze (A)

The Analyze part is the part of the process in which it will try to find the alternatives or the solutions that would be better for the overall flow of the business or the company. Through the analysis part, businesses and organizations can formulate better plans and a lot more sensible processes.

Improve (I)

After an Analysis, the next big step would be the improvement of the step or the process. The improvement stage is what most businesses and organizations focus on because this would be the “game-changer” of your business. Without improvement, then the change that you ought to have for your business or your company would be put to waste. It’s the most important and the most essential part of business process improvement.

Control (C)

Last but definitely not the least would be the control phase, and in this phase, businesses and companies would need to find out different ways on how it can be improved and developed consistently and automatically. The Control Phase is the last phase and although it’s the final part, it doesn’t end there. It doesn’t end as it will go on until the end of the operations of the processes of the business or the process.

The Best Lean Six Sigma Curriculum in the Country

It might be a pain in the neck to find the best, but today is your lucky day. We here at Lean Six Sigma Curriculum Experts have always been working our hardest to provide our clients with the best and the highest quality of Lean Six Sigma Training and Curriculum.

For years, we never stopped innovating and developing our services to match the demand and the requirement of our clients. Now, the curricula for the Yellow Belt and the Green Belt that we have are considered by many businesses and organizations as the best and the most effective.

Should you find yourself needing assistance or the help of the best, never hesitate to give us a quick buzz here at Lean Six Sigma Curriculum Experts. You will never be able to find another company as adept and as skilled as us!

How is the Lean Six Sigma DMAIC Process Defined? Don’t worry – we got you! You’ll not only learn what the DMAIC is, but you will also get the opportunity to learn how you can successfully and effectively implement it into your business processes!